Establishment of optimized process for developing new products. This process was established through development conference for the enhancement of development capability.

R&D SYSTEM

Review Process

Design

Basic Design, Primary Consultation on Process, 3D Modeling, Dynamic Analysis Process Review

Prototyping

We have excellent analysis ability to identify material and technical factors required for production and estimate related cost, as well as manufacturing ability over entire prototyping process using 3D printer, welding and precision machining tools.

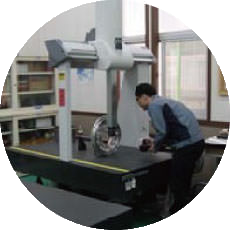

Prototype Testing

With ISO9001 and 14001 certificates and high-tech measuring equipment and test equipment that meet the quality requirements, we concentrate our efforts on enhancing product reliability through heat treatment hardness test, 3D measurement and precision shape measurement.

Product Performance Test

Mechanical products testing for quality assurance(e.g. vibration test and ultra-low-temperature test, etc.) and components performance test, system performance test, environmental test and EMI/EMC testing through accredited institutes to prove our R&D capability for the test and evaluation of electric parts to meet the national defense standards(e.g. wiring system, dashboards, etc.)

Production System

Before mass-production, newly developed products go through optimized process review system once again for the process improvement and cost reduction by reflecting precision processing technology/assembly technology, special machining process technology, surface treatment process design and CNC programming technology.